The manufacturing industry is undergoing a rapid transformation. With more manufacturers now weaving cloud into their business strategies, we’re witnessing an unprecedented shift toward smart factories, predictive maintenance, and AI-driven decision-making.

The numbers portray a clear story: 78% of manufacturers are investing over 20% of their improvement budgets in smart initiatives. Changes like these propelled the APAC smart manufacturing market past $53 billion in 2024.

Yet there’s a challenge. Most organizations still operate legacy ERP, MES, and SCADA systems alongside their shiny new cloud tools. This hybrid reality creates inefficiencies, cost overruns, and operational silos that undermine smart manufacturing goals.

Cloud is not just about scale anymore. To implement it correctly, manufacturing businesses need to put efforts into optimization and visibility. Getting cloud strategy right is foundational to smart manufacturing success.

Legacy Systems: The Invisible Drag on Innovation

Why do legacy systems persist when the smart manufacturing revolution is knocking? The reasons are understandable. They’re built on decades of custom configurations, strict compliance requirements, and the very real fear of operational disruption. But beneath this comfort zone is a financial challenge that’s quietly consuming innovation budgets.

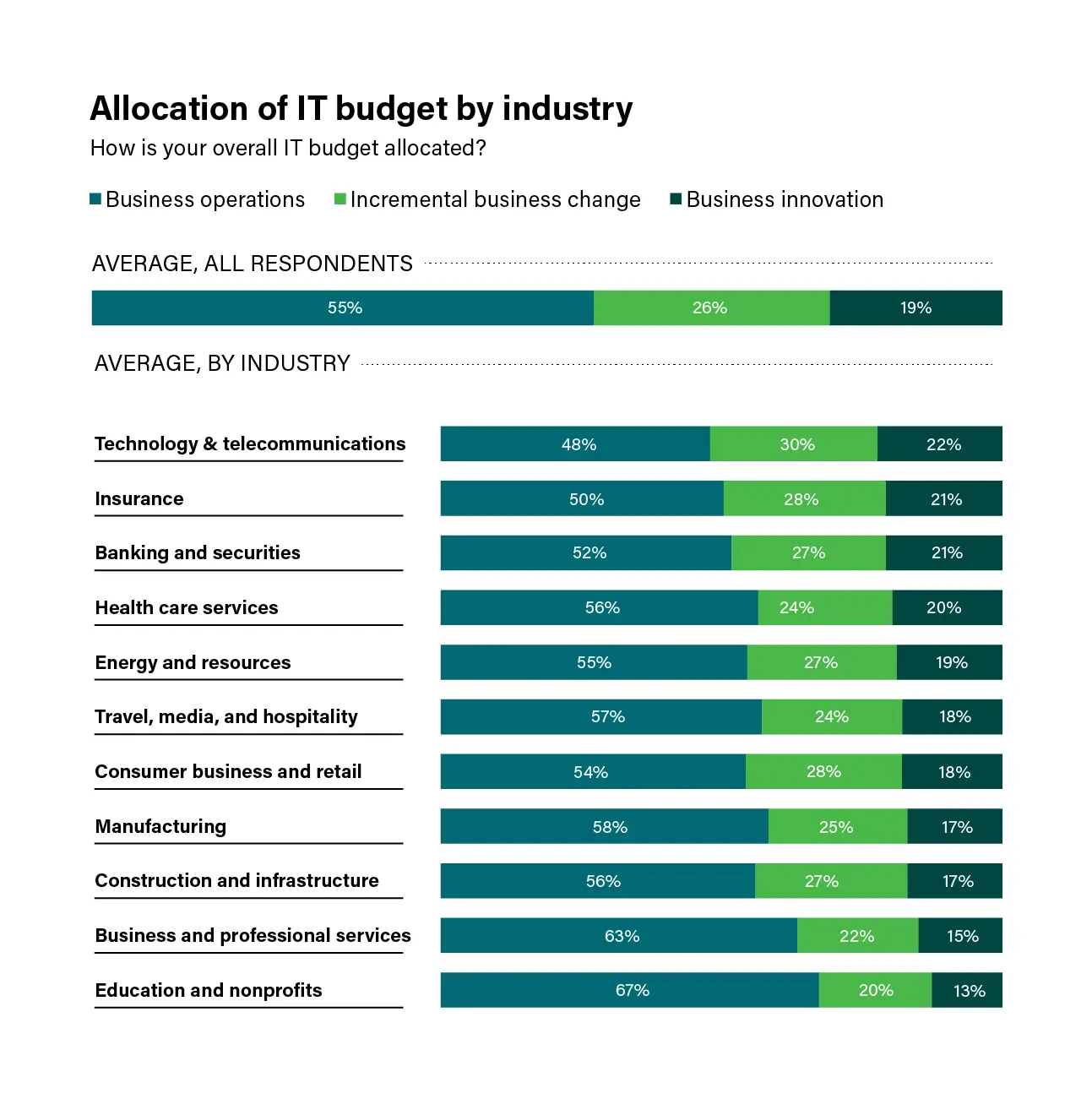

These legacy systems consume up to 80% of IT budgets purely for maintenance. For manufacturers, 58% of total IT spending is going toward keeping old systems alive, while only 17% funds go toward actual innovation. In simple words, it means spending most of your resources maintaining a horse-drawn carriage while competitors race ahead in sports cars. And no manufacturer (big or small) will ever wish that.

The hidden costs compound daily. High licensing and upgrade fees pile up alongside expensive hardware dependencies that tie your operations to outdated infrastructure. Data sits trapped in isolated silos, forcing teams into manual processes that should have been automated years ago. If you retire these legacy systems today, you could significantly reduce hardware and operational costs.

The operational reality is even more painful. Limited OT and IT integration reduces agility exactly when markets demand rapid response. Downtime and maintenance cycles are stretching longer and costing more, while manufacturers waste nearly a whole work week on debugging issues largely stemming from legacy tool dependencies.

Every dollar spent propping up yesterday’s technology is a dollar not invested in building competitive leverage for tomorrow.

The Smart Factory Vision Needs a Smarter Cloud Strategy

Smart manufacturing is a reality, but only for organizations that align their cloud strategy with their factory floor operations. The vision is clear. However, most businesses fail to build and execute a plan to achieve it.

What Manufacturing Leaders Want?

The smart factory wishlist is ambitious: predictive maintenance that prevents failures before they happen, real-time analytics that optimize production in milliseconds, AI-driven forecasting that anticipates market shifts, and interconnected digital twins that mirror every aspect of operations.

Current technology adoption shows a serious commitment to it. According to a report by Deloitte, 41% of manufacturers are investing heavily in factory automation hardware, while 40% prioritize investments in data analytics. Another 38% focus on advanced production scheduling systems, and 34% are implementing comprehensive Manufacturing Execution Systems.

The results justify the investment. Manufacturers deploying smart technologies report production output increase of 10% to 20%, employee productivity gains of 7% to 20%, and unlocked capacity of 10% to 15%. These aren’t marginal improvements, they’re your competitive differentiators.

How Cloud Infrastructure Must Respond?

To support these demanding applications, cloud infrastructure must be fundamentally different from traditional IT deployments. It needs to be elastic, scaling up and down with fluctuating workloads without manual intervention. It must provide visibility, ensuring teams know exactly who’s consuming what resources and when. Most critically, it has to be efficient, reducing waste and redundancy that traditional cloud deployments often create.

Without proper optimization, even the smartest factory investments devolve into cloud chaos and runaway costs.

CtrlS Cloud Optimize: Built for Smart Manufacturing Realities

Most cloud solutions treat manufacturing like any other industry. CtrlS Cloud Optimize recognizes that smart manufacturing demands a fundamentally different approach, one that bridges the gap between ambitious digital transformation goals and operational reality.

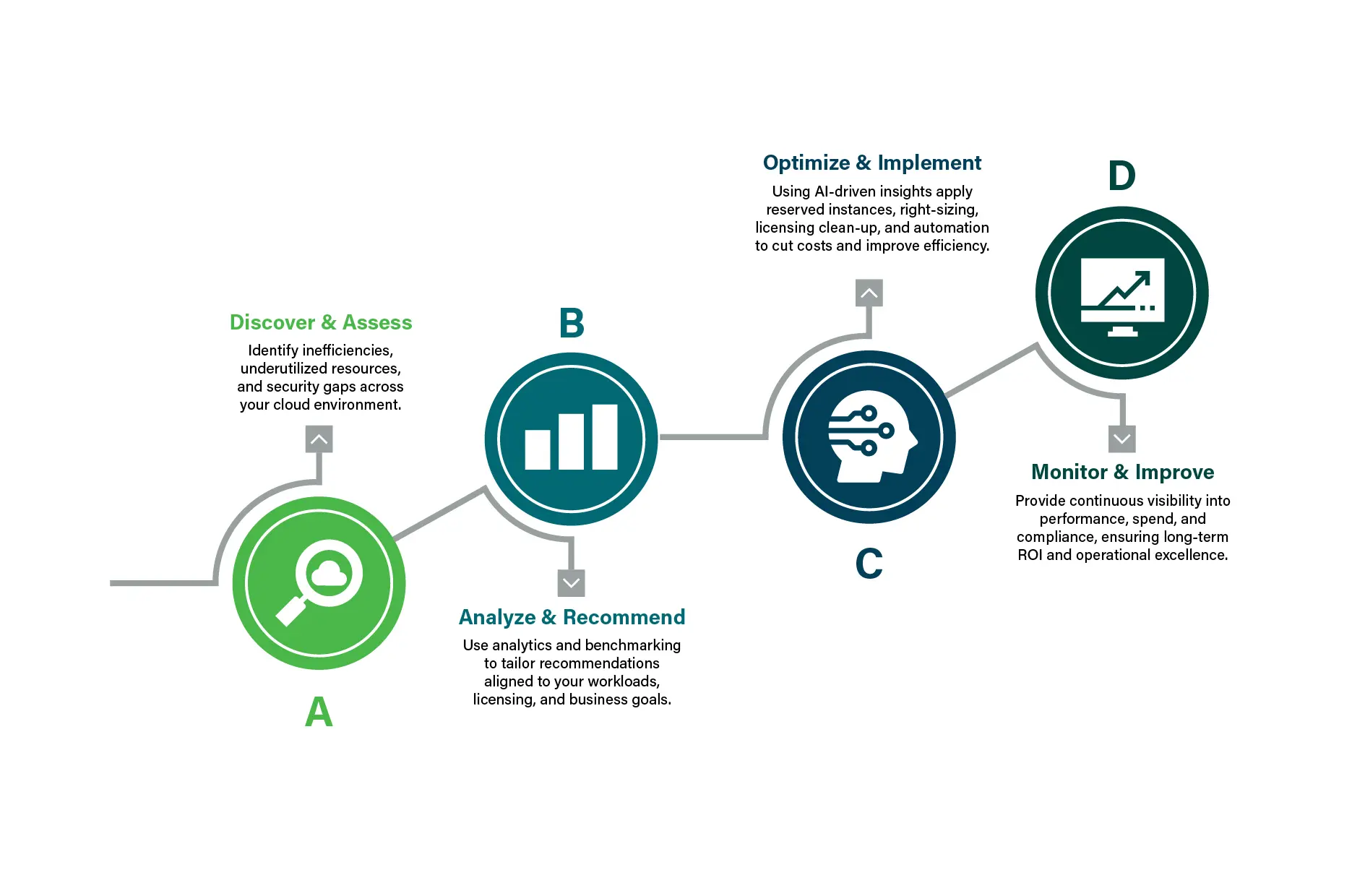

We help manufacturers evolve from basic cloud adoption to strategic cloud optimization. Here’s how:

1. Hybrid Modernization That Respects Your Reality

Your ERP system has been running production for fifteen years. Your MES controls critical processes. These aren’t systems you can rip and replace overnight, nor should you have to. CtrlS Cloud Optimize enables hybrid modernization that keeps mission-critical legacy systems operational while optimizing the cloud workloads surrounding them. This approach lets you innovate without risking operational stability, creating a bridge between where you are and where you need to be.

2. Real-Time Visibility Across Your Entire Manufacturing Stack

Manufacturing environments are complex ecosystems where ERP, MES, IoT sensors, and analytics platforms must work in sync. CtrlS provides comprehensive visibility across all these workloads, giving you a unified view of resource consumption, performance bottlenecks, and optimization opportunities.

You can finally answer questions like:

- Which factory applications are driving cloud costs?

- Where are compute resources sitting idle?

- How are IoT data streams impacting storage costs?

3. Cost Governance Designed for Manufacturing Operations

Generic cloud cost management treats all workloads the same. Manufacturing workloads aren’t the same. CtrlS Cloud Optimize provides granular cost governance that lets you predict, monitor, and control spending at the right level. It covers every factory, application, and production line. This granularity enables informed decisions about where to invest optimization efforts for maximum impact.

4. Intelligent Automation That Understands Manufacturing Workloads

Our automation goes beyond basic resource scheduling. CtrlS continuously right-sizes compute and storage based on actual manufacturing patterns. It then automatically removes idle resources during planned downtime and optimizes backup and storage tiers based on production schedules and compliance requirements. The system learns your operational patterns and adjusts accordingly.

5. OT-Friendly Cloud Integration for Connected Operations

Manufacturing optimization should also cover operational technology integration. CtrlS provides edge-to-cloud observability and optimization specifically designed for connected machines and industrial IoT environments. This ensures your smart factory initiatives have the responsive, cost-effective cloud foundation they need to deliver results.

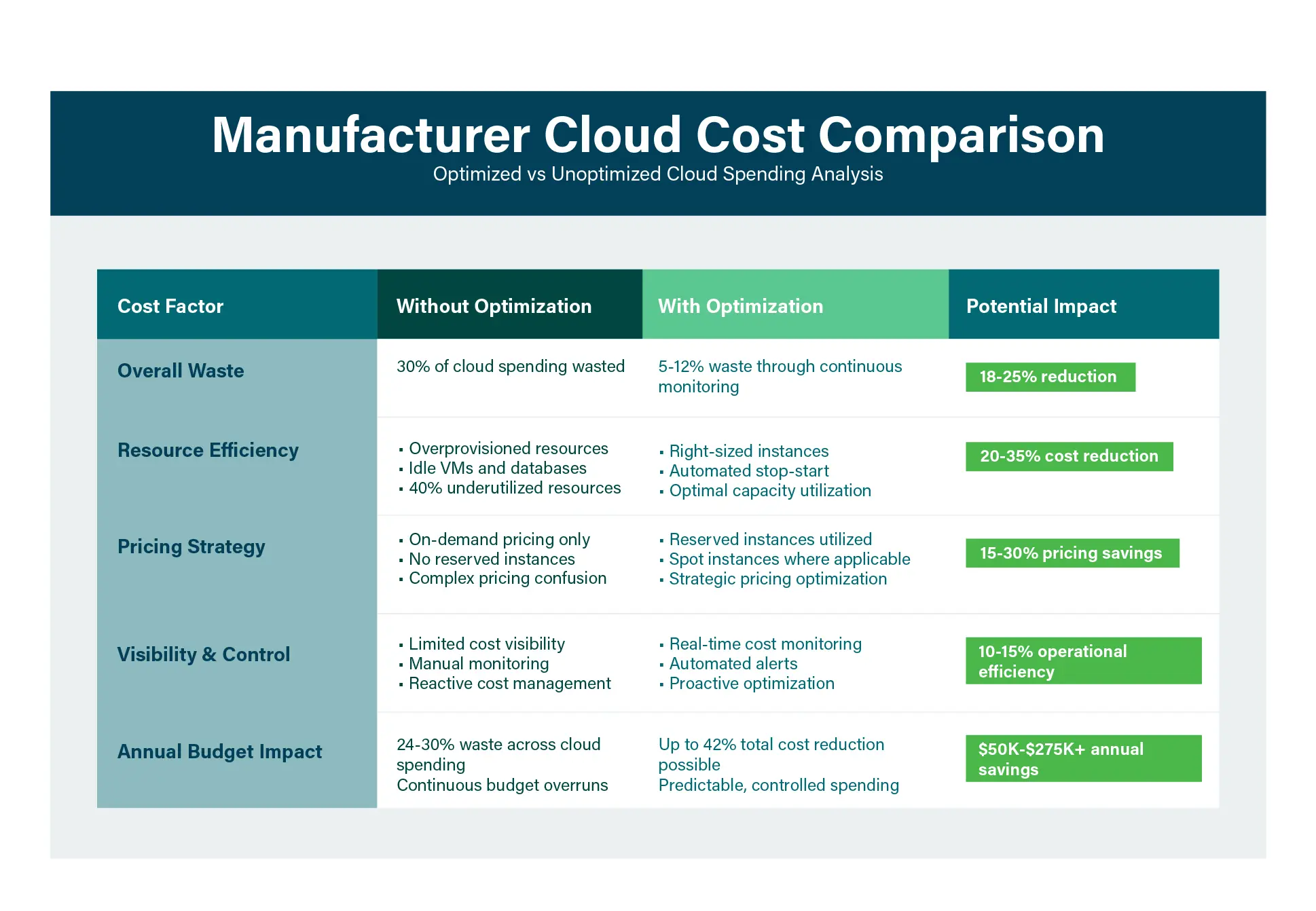

With CtrlS cloud cost optimization, this is the kind of result you can expect:

Industry 5.0 Needs Optimization 2.0

Deploying smart tech is only a part of the Fifth Industrial Revolution. It’s equally essential to deploy them sustainably. Industry 5.0 promises unprecedented connectivity, intelligence, and automation, but these capabilities are meaningless if they’re financially unsustainable or operationally inefficient.

Industry 5.0 requires a new paradigm, which we refer to as “Optimization 2.0,” that aligns with the speed and intelligence of modern manufacturing operations. Real-time production decisions can’t wait for monthly cost reports or quarterly optimization reviews. When a production line needs immediate compute resources for quality analysis, or when predictive maintenance algorithms detect an anomaly, the cloud infrastructure must respond instantly while maintaining cost discipline.

AI and machine learning workloads in manufacturing are particularly compute-intensive. These applications can deliver transformative ROI. They predict equipment failures, optimize production schedules, identify quality issues before they impact customers, and much more. But without intelligent optimization, these same workloads can generate cloud bills that completely eliminate their business value.

Edge data presents another critical challenge. IoT sensors generate massive data streams that require intelligent routing and storage decisions. Simply dumping this data into expensive cloud storage silos isn’t sustainable, especially when much of it has limited long-term value. Smart manufacturers need optimization systems that can automatically tier data based on business value, operational requirements, and compliance needs.

Cost efficiency is the foundation that enables scaling smart factory initiatives from pilot projects to enterprise-wide reform.

Conclusion: Start Smart, Scale Smarter

Smart manufacturing begins with a smart cloud foundation. The high adoption rate among manufacturers shows that cloud isn’t just another technology choice; it’s a necessity for competitive manufacturing.

But adoption alone isn’t enough. Manufacturers who do it well understand that the path from smart factory vision to reality runs through intelligent cloud optimization. CtrlS Cloud Optimize enables this transformation by helping manufacturers modernize gradually without waste, control cloud spend across complex hybrid systems, and power innovation with a leaner, more resilient IT backbone.

The question isn’t whether to optimize, it’s how quickly you can start. And CtrlS can help you start today. Contact Us!

Venkat Subrahmanyam, Vice President – Managed Services, CtrlS Datacenters

A highly experienced and results-driven professional with over 18 years of experience in datacenter infrastructure, private cloud, and public cloud management, Venkat is adept at leading cross-functional teams to design, implement, and manage large-scale datacenter infrastructure and cloud projects. He carries a proven track record of delivering projects on time and within budget while ensuring high levels of customer satisfaction.